A Biased View of Motorcycle Parts New Zealand Specialists

Table of ContentsMotorcycle Parts New Zealand Specialists - The Facts7 Easy Facts About Motorcycle Parts New Zealand Specialists Shown9 Easy Facts About Motorcycle Parts New Zealand Specialists ShownMotorcycle Parts New Zealand Specialists Fundamentals ExplainedA Biased View of Motorcycle Parts New Zealand SpecialistsThings about Motorcycle Parts New Zealand SpecialistsNot known Facts About Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?

So, connect to one of our professionals today.CNC machining modern technology is rapidly coming to be the prime focus of various production procedures around the world as a direct outcome of its numerous advantages over other approaches. Furthermore, the markets that produce bikes have jumped on board with this fad. The most innovative companies are currently developing their engine components and wheels utilizing machining techniques initially developed for motorcycle parts.

On the other hand, the impacts of market are the main emphasis of this short article. Let's get directly right into it. You might be questioning why we utilize. It is not hard to fathom the aspects that brought about this outcome. Now that we have your attention allow us discuss the rationale behind this contemporary development in the motorbike production market.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

Additionally, you have complete control over the appearance of the components, also down to the minute information. Sometimes, motorcyclists might make a decision to fix up their ride by setting up aftermarket elements or customizing the bike's makeover. Once more, computer system numerical control (CNC) machining is one of the most sensible method. Upgrades might be of any kind and design you want.

6 Simple Techniques For Motorcycle Parts New Zealand Specialists

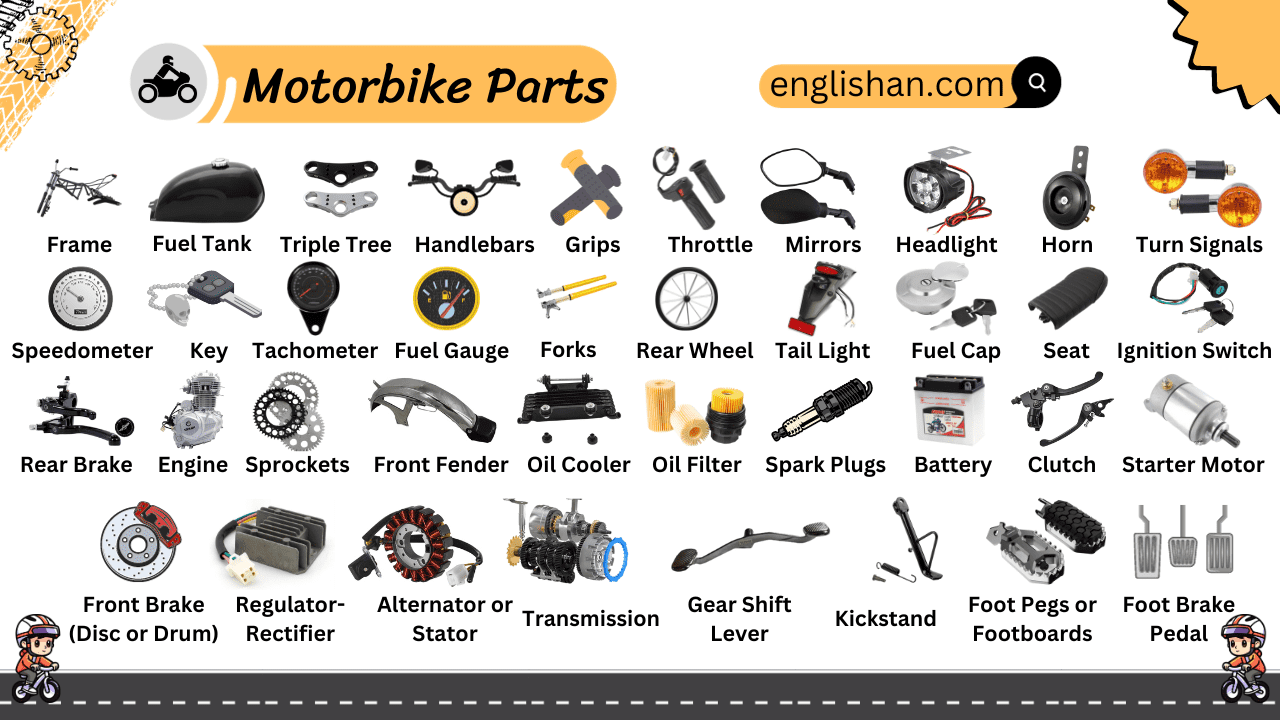

CNC machining may be utilized to make mostly all of a bike's steel and plastic parts. To proceed, we'll review a number of machined components for bikes. In contrast to those on vehicles, wheels on motorcycles have a tendency to be a lot more obvious. As a result, the bike's appearances may be boosted with the appropriate personalization of these wheels.

Milling treatments are utilized to get the desired degree of wheel personalization. Another facet of the motorcycle that may be individualized is the tires.

The Best Guide To Motorcycle Parts New Zealand Specialists

When it pertains to a lorry (or a motorbike), one of the most important part is the engine. Several people suggest to it as the "heart" of the vehicle. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be detailed and require styles with a high level of precision.

Lighting is another complex aspect of modification. Usage only high-quality products, however, because these lights are vital for the security of motorcyclists and other drivers or people when driving, specifically you can try this out during the night. Motorcycle fronts lights have 3 primary components: the light bulb, or light, the lens, and the real estate. In particular, we tailor the lens and the housing.

Milling processes with a perfect coating would certainly lead to the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not made up of vulnerable materials; rather, it is constructed out of difficult polymers that can be machined right into more intricate patterns.

9 Simple Techniques For Motorcycle Parts New Zealand Specialists

Motorbike manufacturers commonly cast these elements, however only for the manufacturing of bespoke parts. Machining on five axes more info here in today's globe is the ways by which any type of style shape might be understood.

The success of the procedure is contingent on the mill cutters' ability to calculate refined and complex angles properly. Select Runsom for your tailored motorbike components! We have the capacity to produce difficult and trendy elements making your motorcycle matchless. Most are crafted from aluminum or steel alloys, each of which has its usages and advantages.

Below are a couple of examples of steels often made use of in bike component machining. Light weight aluminum is the key product made use of by companies specializing in creating personalized bike elements to develop many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes another steel that is extremely light in weight and has excellent machining top qualities because of its high mechanical strength. This material might be developed right into almost any kind of shape and maintains its dimensions well. Also mission-critical elements that need a high level of precision might gain from their use.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Another metal that sees heavy usage in the production of CNC-customized components is magnesium. It is among the lightest metals that are currently available and has excellent machinability attributes and strength compatible with its low weight. Among the drawbacks of magnesium is that its dirt may conveniently catch fire.

Due to its premium machinability and weldability, stainless steel is an alloy that is especially appropriate for from this source CNC procedures. They have wonderful corrosion resistance and a high aesthetic appeal. Their most usual usage in generating different bike parts is bolts, such as screws and screws. Their low vulnerability to oxidation and rust makes them suitable for this usage.

The Best Guide To Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and crushing are the foundational procedures. Nevertheless, alternate strategies exist, such as exploration. Let's examine a lot of these machining methods extensive. The CNC turning strategy is taken into consideration a subtractive production approach. In enhancement, it requires keeping bars of material, frequently plastic or steel, in placement and after that twisting a cutting tool to remove areas of the material as the product is transformed.

These approaches are just as vital and generate components with high accuracy and regular quality. The processes help enhance the general quality of the machined motorbike elements.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Explained